mikester26

- Feb 5, 2013

- 4

- Joined

- Feb 5, 2013

- Messages

- 4

Hi All, I am really stuck with this project and would really appreciate some help

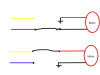

Ok so I have a simple 12v Dc motor with both red and black wires

And I have a device which when detects movement on the x-axis give a +12v on a yellow wire when tilted to the left and +12v on a blue wire when tilted to the right.

Its the motors job to automatically rotate the device left or right (forwards, Backwards) when movement is detected.

Im having trouble figuring out how to wire this thing up, I can only seem to move the motor one way, without physically switching the red and black wires around, what device should I use, thanks

Ok so I have a simple 12v Dc motor with both red and black wires

And I have a device which when detects movement on the x-axis give a +12v on a yellow wire when tilted to the left and +12v on a blue wire when tilted to the right.

Its the motors job to automatically rotate the device left or right (forwards, Backwards) when movement is detected.

Im having trouble figuring out how to wire this thing up, I can only seem to move the motor one way, without physically switching the red and black wires around, what device should I use, thanks