hey , loyal readers & followers of my CDI ignition work ... this is a new project. with a uC not

seen before. prepare for things being on the increase in your life. and riding the leading edge of a wave of knowledge and discovery

the other CDI project with its baseline uC is still underway. the 2 projects are being posted

seperately. and are expected to have similarity and overlap. we'll find out just how much

the plan here is to take a close look at their circuit and assembly code for the CDI ignition at their site.

with the goal of learning the how and what all they did.

they used a mid-range 16F84A uC

the internet is one vast landscape of ideas being presented and shared.

so lets see if we can discover any of the ideas & structure behind their '84A code.

and then have a look at adding any of them to the code work in my other CDI

igniton project posted here in the electronic projects forum

..... ( in addition to the uC assembly code is a link to a CDI circuit different from

the one i am using. it is based on the UC3845 IC. find it at the bottom of

their page in the 'other links' section )

and begin with the recognition that what they have posted may not work.

any part of it and the whole of it all needs to be verified.

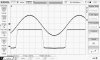

one obvious difference with their work an mine is they are working with

a 2-cycle engine, while mine is a 4. and by their timing diagram it

spins up to 5K RPM before needing any advance.

here is the link to their work :

http://www.sportdevices.co.uk/ignition/ignition.htm

and a note to clarify programming their *.asm file onto a 84A uC ...

the PicKit-2 and PicKit-3 do both support this uC. but not the 'C84 or '84

i'm counting on help from the readers among you with MPLAB assembly

coding experience in lookup tables,

interrupts and other new code features like cblock expressions.

plus input from dirt- bikers who can confirm a 2-cycle engine not needing any advance

until it gets to 5K rpm

right out of the starting blocks we have to figure out what speed of a clock

they used. its not shown in the circuit or mentioned in the code.

and whatever type of clock it is the '84A uses an external one.

this clock rate is vital to know. coding projects for an ignition system are timing critical.

we use the known clock rate to decide the RPM's . and after that to wait some

amount of time after the flywheel timing pulse to fire the CDI circuit. and thus meet

the timing advance requirement.

seen before. prepare for things being on the increase in your life. and riding the leading edge of a wave of knowledge and discovery

the other CDI project with its baseline uC is still underway. the 2 projects are being posted

seperately. and are expected to have similarity and overlap. we'll find out just how much

the plan here is to take a close look at their circuit and assembly code for the CDI ignition at their site.

with the goal of learning the how and what all they did.

they used a mid-range 16F84A uC

the internet is one vast landscape of ideas being presented and shared.

so lets see if we can discover any of the ideas & structure behind their '84A code.

and then have a look at adding any of them to the code work in my other CDI

igniton project posted here in the electronic projects forum

..... ( in addition to the uC assembly code is a link to a CDI circuit different from

the one i am using. it is based on the UC3845 IC. find it at the bottom of

their page in the 'other links' section )

and begin with the recognition that what they have posted may not work.

any part of it and the whole of it all needs to be verified.

one obvious difference with their work an mine is they are working with

a 2-cycle engine, while mine is a 4. and by their timing diagram it

spins up to 5K RPM before needing any advance.

here is the link to their work :

http://www.sportdevices.co.uk/ignition/ignition.htm

and a note to clarify programming their *.asm file onto a 84A uC ...

the PicKit-2 and PicKit-3 do both support this uC. but not the 'C84 or '84

i'm counting on help from the readers among you with MPLAB assembly

coding experience in lookup tables,

interrupts and other new code features like cblock expressions.

plus input from dirt- bikers who can confirm a 2-cycle engine not needing any advance

until it gets to 5K rpm

right out of the starting blocks we have to figure out what speed of a clock

they used. its not shown in the circuit or mentioned in the code.

and whatever type of clock it is the '84A uses an external one.

this clock rate is vital to know. coding projects for an ignition system are timing critical.

we use the known clock rate to decide the RPM's . and after that to wait some

amount of time after the flywheel timing pulse to fire the CDI circuit. and thus meet

the timing advance requirement.

Last edited: