Hi everyone, I'm new here and looking to solve a problem I have with burnt out contacts on my boat.

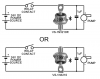

The problem is with a 24 volt fresh water pump that was continuously burning out pressure switches. I partially solved the problem by bypassing the pump's internal pressure switch and using a simple external one attached to a 30/40 amp relay that has a diode across it. The diode has protected the simple micro-switch that operates the relay, but the relay's contacts fail with monotonous regularity, maybe lasting 6-8 weeks with daily use.

I've decided to get proper water pressure regulation by installing a mains operated Square D switch. This will ensure a usable pressure range of 20 to 40 PSI. However, this switch also has contacts and I want to protect them with an MOV. I have found that Littelfuse have a V20E25P that will do the job nicely, but their postage costs are ridiculous! I'm having problems though in finding a similar spec MOV. Can anyone suggest a more readily available alternative. Spec below.

Manufacturer: Littelfuse

Product Category: Varistors

RoHS: RoHS Compliant Details

Brand: Littelfuse

Product: MOV

Voltage Rating DC: 31 V

Voltage Rating AC: 25 V

Clamping Voltage: 77 V

Peak Surge Current: 8000 A

Surge Energy Rating: 120 J

Capacitance: 12000 pF

Operating Temperature Range: - 40 C to + 85 C

Packaging: Bulk

Case Diameter: 23 mm

Case Width: 5 mm

Current Rating: 1 mA

Dimensions: 23 mm Dia. x 5 mm W

Lead Spacing: 8.5 mm

Mounting: Radial

Series: LV UltraMOV

Factory Pack Quantity: 500

Varistor Voltage: 39 V

Littelfuse part# V20E25P

Many thanks for any advice. Stu

The problem is with a 24 volt fresh water pump that was continuously burning out pressure switches. I partially solved the problem by bypassing the pump's internal pressure switch and using a simple external one attached to a 30/40 amp relay that has a diode across it. The diode has protected the simple micro-switch that operates the relay, but the relay's contacts fail with monotonous regularity, maybe lasting 6-8 weeks with daily use.

I've decided to get proper water pressure regulation by installing a mains operated Square D switch. This will ensure a usable pressure range of 20 to 40 PSI. However, this switch also has contacts and I want to protect them with an MOV. I have found that Littelfuse have a V20E25P that will do the job nicely, but their postage costs are ridiculous! I'm having problems though in finding a similar spec MOV. Can anyone suggest a more readily available alternative. Spec below.

Manufacturer: Littelfuse

Product Category: Varistors

RoHS: RoHS Compliant Details

Brand: Littelfuse

Product: MOV

Voltage Rating DC: 31 V

Voltage Rating AC: 25 V

Clamping Voltage: 77 V

Peak Surge Current: 8000 A

Surge Energy Rating: 120 J

Capacitance: 12000 pF

Operating Temperature Range: - 40 C to + 85 C

Packaging: Bulk

Case Diameter: 23 mm

Case Width: 5 mm

Current Rating: 1 mA

Dimensions: 23 mm Dia. x 5 mm W

Lead Spacing: 8.5 mm

Mounting: Radial

Series: LV UltraMOV

Factory Pack Quantity: 500

Varistor Voltage: 39 V

Littelfuse part# V20E25P

Many thanks for any advice. Stu