Hi all. I'm new at this and considering repair of a motorised walk-behind straight-ahead (i.e. no reverse, no direction control) golf buggy. Manufacturer was Boska (defunct), power is 12v 28Ah deep cycle battery.

The buggy was assembled in the car park and behaved itself until 100M down the first hole whereupon it took off by itself. Battery disconnect was the only remedy. The buggy did not respond to the pot attached to the handle, which normally controls on-off and speed.

I have checked the operation of the pot and it is good - O/C in the OFF position, big ohms in slow position rising to low ohms in the fast position.

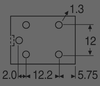

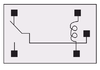

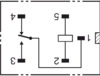

I can't find a circuit diagram for the motor controller board. However, inspection reveals blistering of the OKO K3B12 relay (see pdf attached) casing. Within this 5-pin relay, there is 320 ohms across the coil pins (as per spec) but all other pin connections are O/C. There should be connectivity between at least one other pair. If this is the culprit, I haven't been able to find a replacement source.

Any suggestions on how to proceed?

Re the graphics, at the top right of Picture A there is a sort of springy collar which fits around but doesn’t touch the motor -ve terminal and clamps lightly on another component. Is the collar just a heat sink? Anyway, I took it off and snapped picture E so you could see the trace beneath it.

Picture G is my fishing boat.

Thanks for looking.

The buggy was assembled in the car park and behaved itself until 100M down the first hole whereupon it took off by itself. Battery disconnect was the only remedy. The buggy did not respond to the pot attached to the handle, which normally controls on-off and speed.

I have checked the operation of the pot and it is good - O/C in the OFF position, big ohms in slow position rising to low ohms in the fast position.

I can't find a circuit diagram for the motor controller board. However, inspection reveals blistering of the OKO K3B12 relay (see pdf attached) casing. Within this 5-pin relay, there is 320 ohms across the coil pins (as per spec) but all other pin connections are O/C. There should be connectivity between at least one other pair. If this is the culprit, I haven't been able to find a replacement source.

Any suggestions on how to proceed?

Re the graphics, at the top right of Picture A there is a sort of springy collar which fits around but doesn’t touch the motor -ve terminal and clamps lightly on another component. Is the collar just a heat sink? Anyway, I took it off and snapped picture E so you could see the trace beneath it.

Picture G is my fishing boat.

Thanks for looking.

Last edited: