Hello,

I am trying to arrive at a circuit design that dims an LED string with each push of a button. The LED's string is about 1m long and powered by 12V (from the mains).

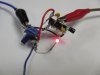

One idea was to use a 555 timer to set the frequency for the LED's (as in Pulse Wave Modulation) - and using a 4017 counter chip - a different output pin would be selected (which would have a slightly different resistor - and so change the output frequency of the 555) - and the LED string would go dimmer with each button push.

Or another chip that maybe able to be used is the LM3404.

So - my questions are:

1. Would the 4017/ 555 idea work - comments?

2. Would the LM3404 work? If so what would the cicuit be? Also - would it be better than the 4017/555 idea?

3. Does anyone have a circuit schematic for an LED dimmer, push button, powered by 12V

Any help/ comments appreciated.

Thanks - Angus

I am trying to arrive at a circuit design that dims an LED string with each push of a button. The LED's string is about 1m long and powered by 12V (from the mains).

One idea was to use a 555 timer to set the frequency for the LED's (as in Pulse Wave Modulation) - and using a 4017 counter chip - a different output pin would be selected (which would have a slightly different resistor - and so change the output frequency of the 555) - and the LED string would go dimmer with each button push.

Or another chip that maybe able to be used is the LM3404.

So - my questions are:

1. Would the 4017/ 555 idea work - comments?

2. Would the LM3404 work? If so what would the cicuit be? Also - would it be better than the 4017/555 idea?

3. Does anyone have a circuit schematic for an LED dimmer, push button, powered by 12V

Any help/ comments appreciated.

Thanks - Angus