Ian submitted a new Showcase Item:

K40 Laser Cutter

Read more about this showcase item here...

K40 Laser Cutter

After much deliberation and questions on the forums, I finally bought a K40 laser cutter. It cost around £350 (after discounts) and was delivered within 2 days from a UK warehouse - which means I can avoid any lengthy delays and import fees from ordering direct from China. Here's the model I went for:

https://www.aliexpress.com/item/UK-...-Engraver-Cutter-woodworking/32810421426.html

I'd like to think I've got quite realistic expectations for this laser cutter, as it barely cost much more than it would be to buy a cheap 40W CO2 laser tube. I know it'll need a lot of tinkering to get the most of it, which is half the fun.

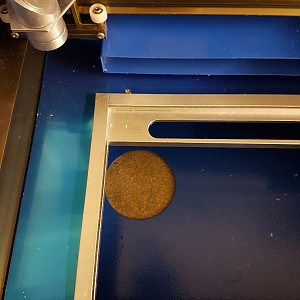

It was packaged securely and arrived without a scratch - thankfully the glass laser tube survived the journey:

View attachment 40255

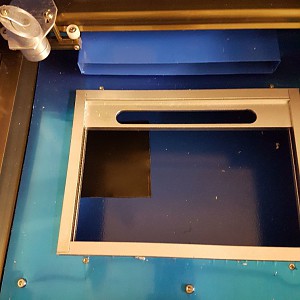

A few accessories were provided, tucked away inside the lid:

View attachment 40256

There was a manual in English, software CD + license dongle, water pump (for liquid cooling), extractor fan and hose. The only other thing that is required is a bucket or similar container, plus some distilled water to circulate through the laser tube.

For some odd reason, the laser cutter comes with castors - but it's clearly designed to be used on a workbench. Before I did anything else, I unscrewed the nuts from within the chassis to remove these.

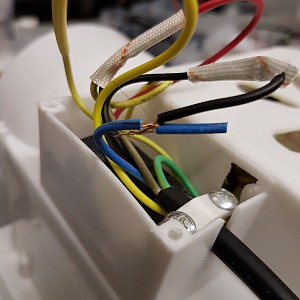

Before powering the laser cutter up, I gave the machine a once over to check all of the connections. Thankfully, the quality within the main unit seems acceptable - there were a few connections that had bootlace ferrules a little too long (not dangerous, but I gave them a trim and reconnected them). It's cheaply fabricated but seems solid enough. However, I'm a little concerned that there is no laser interlock for the lid, so this is one of the things I'll be changing as soon as possible.

Here's a photo of inside the electronics bay (the loose connection was intentional!):

View attachment 40257

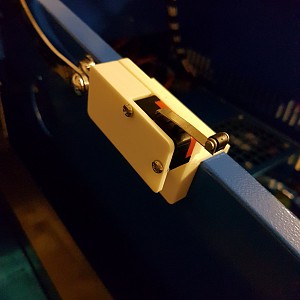

Here's the 40W CO2 laser tube, underneath a cover at the rear of the unit:

View attachment 40258

The laser tube was manufactured only a couple of months ago, so it's comforting to know it wasn't sat on a shelf for a year or two before I used it.

The gantry system within the laser cutter uses basic linear rails to control the X and Y axis, and there's an awfully small clamp build in to the cutting bed. The total cutting area is around 300x200mm, but the clamp can only hold around half of this...

Read more about this showcase item here...