I have looked at many DIY power supplies and most just use a heat sink (with no fan) whose size varies enormously.

There are several video's on Youtube showing the 2N3305 being replaced, probably due to being cooked. One was only a 2A 14V transformer. Internal heat sink, no vents.

I felt sure that a large heat sink (or 2) and fan with a large vent area would dissipate more heat.

In one of the video's this chap does he says that for every 10 Deg C drop you double the life of the power transistor.

I have been concerned about these insulating pads reducing heat flow, I was right (makes a change).

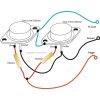

It seems you can have several 2N3305's on the same heat sink metal to metal with paste. The heat sink would of course have to be insulated from the case.

This all started because I have found it difficult to get the insulating washers. I'm glad I did and after you have seen the video you will see why.

I wanted to make a system that could control the full output of this 160W transformer. Being a linear system that will mean a lot of heat.

I understand that the 2N3305 can handle lots of power but the lower the temperature the better. 1 x 2N3305 could carry the amps but not the watts in heat dissipated. I am going to end up with say 54v and 4.44A going into the regulator as a peak load. That's 240W. I was considering 4 x 2N3305's.

I am now confused as my voltmeter reads 54V DC and I assume the amps is still around the rated value of 4.44A. The transformer is rated at 160W at 36V AC at 4.44A - not 240W.

HELP ! Where have the watts come from ? Is it the 1.4141 creeping in again ? That brings it up to 226W. (160 x 1.4141)

Whatever mistake I have made I have read that abut 30W is the max a TO – 3 package can run at. I suppose I could always add a thermal cut out set at 80C.

This is the video about heat transfer, it's quite good. DIY Bench Power Supply#11

There is one before this - DIY Bench Power Supply #10 but #11 gives the results.

I hope the above makes sense - please remember I know very little and that this is a project (and will be used as well) but not the only solution. Hopefully that's on it way by bullock cart from China - A Buck Convertor - Banggood 400w 60V. If it's 200W I'll be more than happy.

Any advice on the above would be very much appreciated.