Marsh Lane

- May 27, 2017

- 10

- Joined

- May 27, 2017

- Messages

- 10

Hello all,

Im new to the forum, so hopefully posting in the right place. Im just getting into electronics, but am a bit new to things!

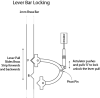

Currently, I'm working on a little home project involving a lever that is connected to some 2mm brass bar. As the lever moves forwards and backwards, the brass bar moves as well. Now at some points I need to lock the lever, so my idea is a small wedge cut out in the forward and backward positions (shown as F and B on the attached drawing), now that bit I'm fine with, but my thought was to move the 'U' shape that pushes or pulls the 'wedges' into position using an Actulator or Solenoid to create linear movement.

I can control the power to the device using an electronic circuit no problem. But the issue is that Actulators seem to be running in the £70-£90 each mark (I'm in the UK), and Im likely to need 10-20 of them, making it very expensive! My other idea was a solenoid, but given that it may remain powered for some time (i.e. upwards of 40-50 minutes) I suspect the solenoids will burn out quickly.

Before I start looking to use stepper motors and create my own form of actuator design (with the inherent problems) can anyone suggest an alternative way of motorising the movement of the 'U' shape? For reference, there may be times when the 'wedges' do not line up immediately, and one wedge is being pushed against the full width of the bar, only dropping into the wedge hole when the lever is moved, hence there does need to be a constant, but not excessive, force until the 'U' has travelled its full distance. Only one of the two wedges will ever be required at any one time.

More than happy to adapt the design to another way of stopping the brass bar (and hence the lever) from moving if anyone has any thoughts.

Activation (or deactivation) of the whole device will be undertaken using relays and logic gates.

Cheers

Richard

Im new to the forum, so hopefully posting in the right place. Im just getting into electronics, but am a bit new to things!

Currently, I'm working on a little home project involving a lever that is connected to some 2mm brass bar. As the lever moves forwards and backwards, the brass bar moves as well. Now at some points I need to lock the lever, so my idea is a small wedge cut out in the forward and backward positions (shown as F and B on the attached drawing), now that bit I'm fine with, but my thought was to move the 'U' shape that pushes or pulls the 'wedges' into position using an Actulator or Solenoid to create linear movement.

I can control the power to the device using an electronic circuit no problem. But the issue is that Actulators seem to be running in the £70-£90 each mark (I'm in the UK), and Im likely to need 10-20 of them, making it very expensive! My other idea was a solenoid, but given that it may remain powered for some time (i.e. upwards of 40-50 minutes) I suspect the solenoids will burn out quickly.

Before I start looking to use stepper motors and create my own form of actuator design (with the inherent problems) can anyone suggest an alternative way of motorising the movement of the 'U' shape? For reference, there may be times when the 'wedges' do not line up immediately, and one wedge is being pushed against the full width of the bar, only dropping into the wedge hole when the lever is moved, hence there does need to be a constant, but not excessive, force until the 'U' has travelled its full distance. Only one of the two wedges will ever be required at any one time.

More than happy to adapt the design to another way of stopping the brass bar (and hence the lever) from moving if anyone has any thoughts.

Activation (or deactivation) of the whole device will be undertaken using relays and logic gates.

Cheers

Richard