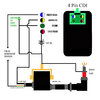

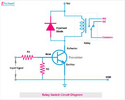

You cannot switch the coil directly with Uno.

Post the wiring diagram you have for the bike, and its maintenance manual if you

have that.

You can consider coding using block programming. mBlock takes your block configuration

and generates Arduino code from that.

The above code is basic, should work. But I would add hysteresis to it. If code trips

at 5000 then ignition comes bak on at. say, 4900 RPM, 100 RPM is the hysteresis.

That helps with noise issues from RPM sensor. Easy to code and add.

Here is code it generated that you program into part using Arduino IDE :

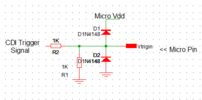

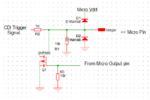

Your interface to the RPM sensor has to meet logic levels allowed into Arduino. Do

you have an oscilloscope ?

Regards, Dana.

Post the wiring diagram you have for the bike, and its maintenance manual if you

have that.

You can consider coding using block programming. mBlock takes your block configuration

and generates Arduino code from that.

The above code is basic, should work. But I would add hysteresis to it. If code trips

at 5000 then ignition comes bak on at. say, 4900 RPM, 100 RPM is the hysteresis.

That helps with noise issues from RPM sensor. Easy to code and add.

Here is code it generated that you program into part using Arduino IDE :

Your interface to the RPM sensor has to meet logic levels allowed into Arduino. Do

you have an oscilloscope ?

Regards, Dana.

Last edited: